REFINEMENT

Scheda del progetto

Università degli Studi di Pavia

Bioingegnere Daniele Pastorelli

Biologa Michela Casanova

Biotecnologa Lorenza Cassano

Whey is the main waste product of the dairy industry. Worldwide, 160 Mton/year of it is produced, 8 in Italy alone. Due to its high organic load, whey cannot be discharged directly into surface waters. The recovery of high feed value proteins by means of ultrafiltration is often carried out to valorise this effluent. Nevertheless, the residual liquid (permeate) still has too high a load due mainly to the lactose content. The permeate is often concentrated to facilitate its transport to purifiers, reaching lactose concentrations of up to 160 g/L.

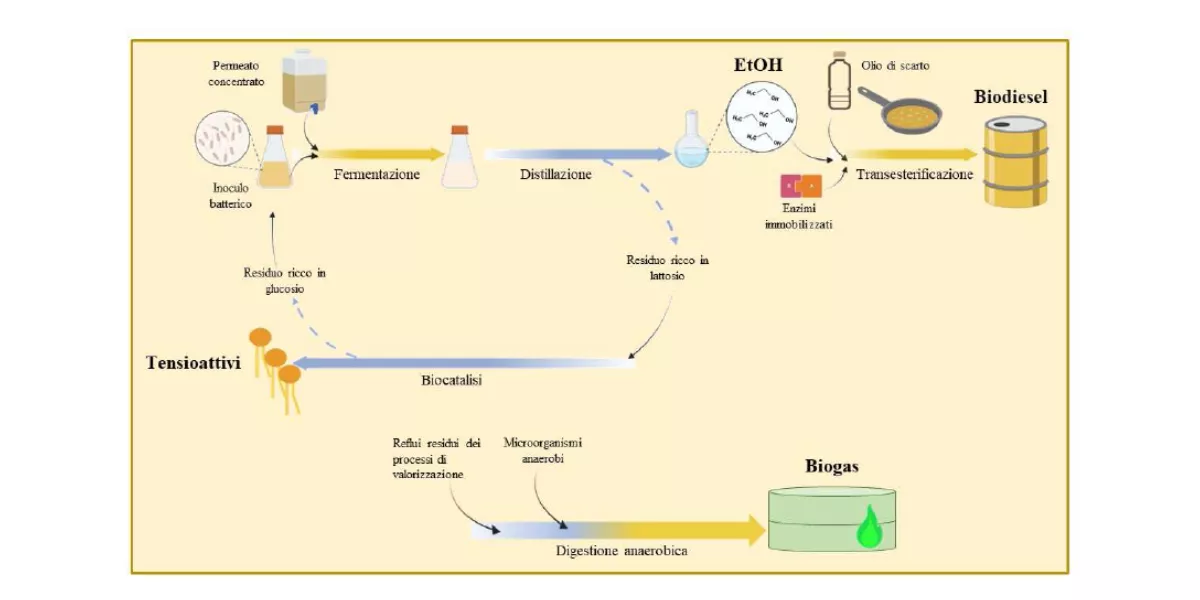

REFINEMENT develops two technologies to create additional value from permeate: ethanol production by fermentation and surfactant synthesis by biocatalysis. Furthermore, it assesses how the integration of the two processes into a single ‘no-waste’ biorefinery can increase sustainability and facilitate technology transfer and business development of the developed know-how. In particular, it studies how the effluents of the two processes, which are currently unused, can be further exploited: the lactose residue at the end of fermentation can be used as a substrate for biotransformations, while the glucose-containing effluent from the biotransformations can be exploited as a medium for the preparation of the bacterial inoculum for pre-fermentation. Thanks to the synergy between the two processes so far considered separately, further added value will be generated from the up-cycling of the by-products by enhancing the circularity of the two processes.

The main challenge is to valorise the waste from two processes to increase the sustainability of a biorefinery, which is already able to produce bioethanol and surfactants efficiently.

Valorisation of surfactant production waste

The waste from the surfactant biosynthesis process is rich in glucose and can be exploited as a growth medium for bacterial biomass to be inoculated into the fermentation process. The utilisation of this waste will have to take into account the presence of solvents used in the reaction, and the development of medium formulations that can guarantee the formation of sufficient bacterial load for high-yield fermentation. The work involves screening for the best growth conditions for the bacterial strain with the aim of reducing inoculum preparation costs by exploiting a waste material.

Valorisation of bioethanol production waste

The main challenge is the use of a waste liquid from fermentation and distillation processes as a substrate for the synthesis of surfactants. The waste liquid will have to contain sufficient amounts of residual lactose to ensure the reaction, and a minimum amount of enzyme inhibitors.

Therefore, the work involves defining the optimal fermentation end-point to meet these requirements, and performing biotransformation tests from this substrate, with the aim of using a lower permeate waste material to carry out surfactant synthesis.

Diversification of biorefinery outputs

Ethanol and its distillation residue will be further processed in order to diversify the output of the processes. In particular, ethanol will be used as a substrate for the production of biodiesel, while the distillation residue will be used in anaerobic digestion processes to produce biogas. The main challenges will be the production of biodiesel and biogas with high efficiency while using heterogeneous substrates, with simultaneous lowering of the pollutant load of the residues of these processes.

Finally, all illustrated tasks will have the additional challenge of evaluating scale-up by means of laboratory and pre-industrial setups being studied by the project team.

The integrated process is highly innovative compared to the state of the art. Through this PoC, the technologies already developed by the laboratories involved will be consolidated and implemented.

The expected impact is to create a ‘no-waste’ biorefinery characterised by the production of a portfolio of bio-based products that are of interest to different market segments (energy, commodities, fine chemicals). The implementation of the biorefinery in an existing business such as a whey valorisation centre may be more advantageous than its implementation in individual dairies because:

- the valorisation centre already possesses the technology for protein extraction and subsequent permeate generation;

- the permeate is a fairly standardised substrate as it is a mix of different types of whey, and its supply is not dependent on season and climate;

- the collection centre already processes considerable volumes of whey and is already equipped and staffed for its valorisation.

The target of the technology investigated and developed in the project concerns companies dealing with the valorisation of dairy waste and aiming at the production of high-value substances.