IMPLEMENTO

MES Implementation and Interconnection of Production Machines

Scheda del progetto

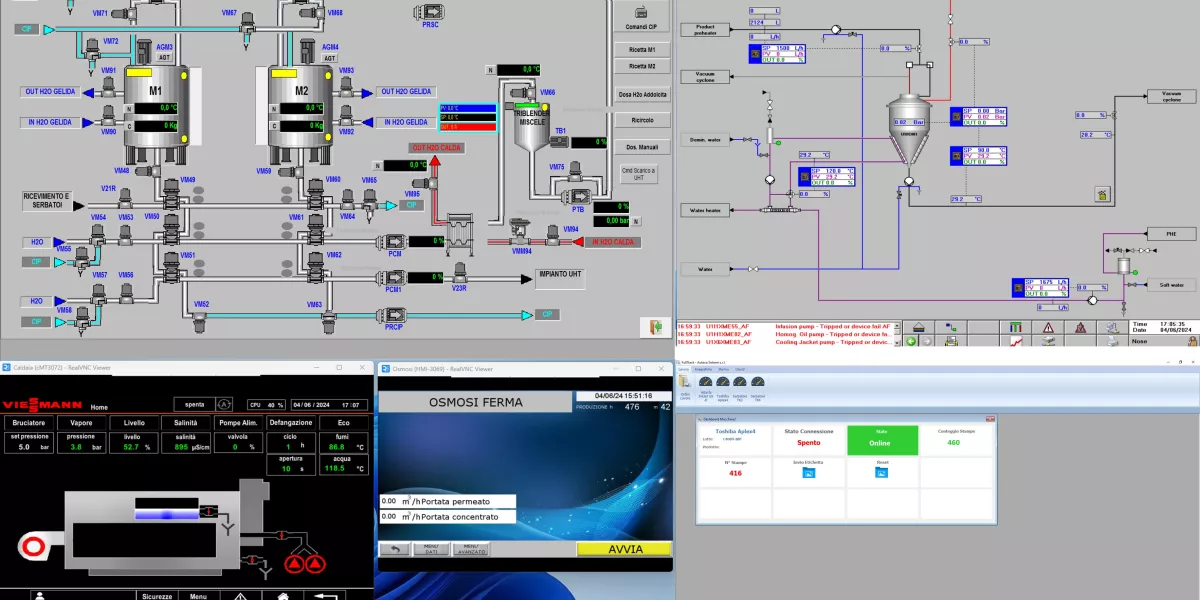

The IMPLEMENTO service involves the interconnection of the machines in production to the company Ethernet network, also through the remote control of equipment not designed to be interconnected to the network.

The project then involves the installation of a data collection software package for product traceability in milk processing. The system allows you to set and detect the batch of the final product and store this data in an archive, linking it to both the processes performed and the raw materials used and the suppliers. All the data set and the processing parameters that can have an impact on the quality of the product will be tracked by the system that stores them in the database matching them to the batch code, through an archive composed of configurable tables.

Contacts:

Lorenzo Muller

lorenzo.muller@pascalsrl.it

The main challenge of the IMPLEMENTO service is to acquire a competitive advantage in terms of improved process control, which can lead to a reduction in production costs, thanks, for example, to the reduction in waste due to a much more precise control of the very early stages of production and, consequently, to the reduction of associated energy costs.

The innovation lies not so much in the technology adopted, but in the process control introduced. Currently, process and quality controls, both in general in the food sector and in the specific case of Pascal, occur by taking a sample to analyze; production stops if an anomaly is found, wasting machine time, energy and gas, as well as disposing of the non-compliant product that can no longer be reprocessed. Real-time control allows continuous monitoring of product parameters (viscosity, density, conductivity) and reduces the margin of error to almost zero.

The acquired know-how can improve company procedures, streamlining operations on the quality management system, reducing related costs and improving the traceability system, to the full advantage of food safety of products.